Laden Seite

Laden Seite

Diaphragm valves allow a secure shut-off of difficult fluid media and a certain control to some extent.

Since only the body and diaphragm get in contact with the media, diaphragm valves are extremely suitable for aggressive fluids. Thanks to the design of FRANK diaphragm valves they can also be used for abrasive and solid-containing fluids. In case of hot, moist chlorine (for chlorine electrolysis for example), we recommend our unique EL-PVDF diaphragm valves. A travel stop mechanism is a standard feature of our diaphragm valves.

The most used connection in the chemical industry is the flange. Our diaphragm valves are also available with true union connections.

For all available nominal diameters, our diaphragm valves also come with pneumatic and electrical actuators.

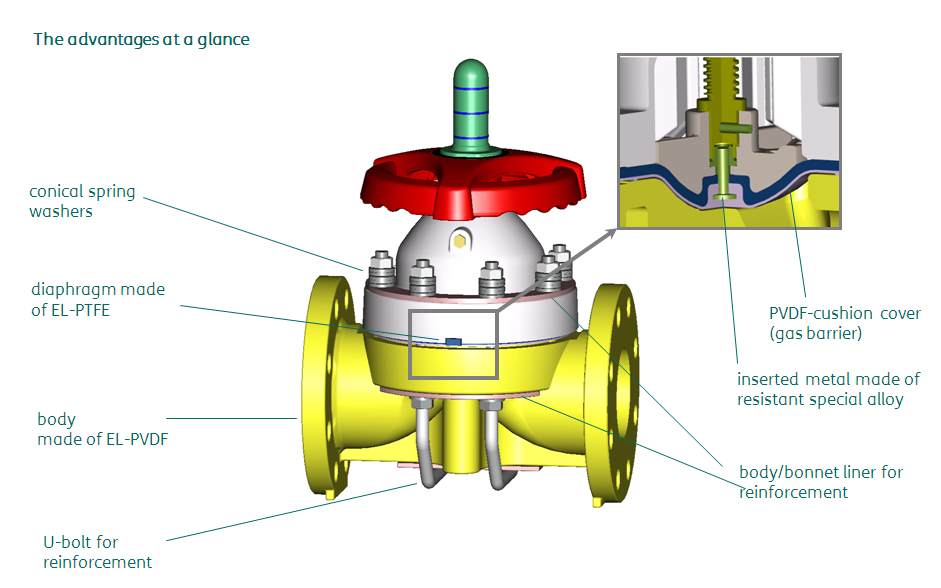

Diaphragm valve type 14 made of EL-PVDF

The alternative for chlorine electrolysis

Permanent contact with free chlorine at high temperatures (conditions which occur in chlorine electrolysis lines for example) may result in bubble formation on the contact surfaces of PVDF valves after about two years of use. After being in use for a longer period of time, the inner surface of the valve may detatch under certain circumstances.

Our solution: The diaphragm valve type 14 made of ELPVDF offering a considerably longer service life than standard PVDF valves. A number of modifications led not only to a longer service life but also to an increased operational stability.