Laden Seite

Laden Seite

EXNER valves have proven themselves in the field of process engineering for over 50 years. As early as the sixties, EXNER developed the first globe control valve made of plastic and layed the foundations for the product range of these control valves and special valves. Today the EXNER valves are produced and developed by FRANK.

Application areas such as the chemical and pharmaceutical industries, steel pickling, chlorine chemistry and water conditioning clearly highlight the advantages of our all-plastic valve technology.

These valves are manufactured in a modern production facility in Mörfelden which has been certified to DIN EN ISO 9001 and ISO 14001. Only tested and certified materials are used. CAD-based design along with differentiated process data monitoring ensure the best possible control valve designs for successful application at our customers plants.

The degree of automation of a plant defines the scope of accessories for control valves. Besides supplying appropriate accessories FRANK’s services also include easy procurement of spare parts.

Steady materials.

Stem tightening by PTFE-bellow.

Due to its excellent mechanical properties and chemical stability FRANK uses a specially modified PTFE. The type DyneonTM TFMTM 1600 PTFE is especially characterized by a lower cold flow and higher resistance to permeation.

Other special materials, such as conductive plastics, complete the range of materials used.

Each valve is checked for proper working order and to rule out leakage.

Material and inspection certificates are supplied according to DIN EN 10204-2.1 respectively DIN 55350 Teil 18.

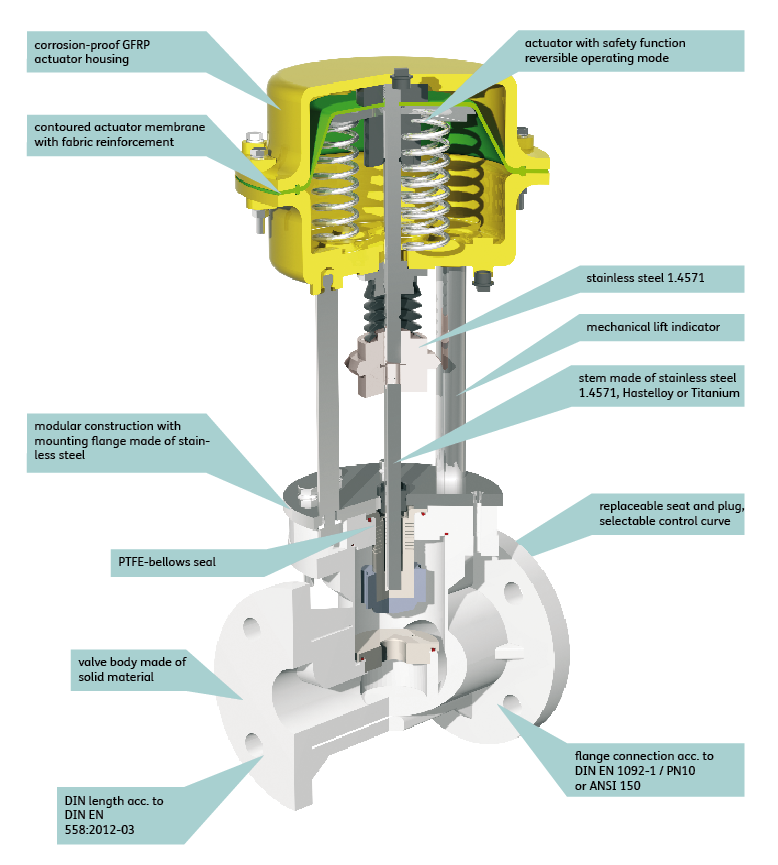

Stable, corrosion-free housing made of duroplastic

The distinctive valve body construction made of solid plastic is enhanced by a sophisticated actuator design. The actuator housing is made of fibre-glass reinforced polyester resin for high mechanical durability. The construction of both corrosion-resistant housing covers is reversible to allow the operating mode to be reversed. The housing holds the colour-coded.

sets of springs which are necessary for the two safety settings - “Normaly OPEN (NO)“ or “Normaly CLOSED (NC)“. The EXNER actuator model K 22O is used for small nominal diameters up to size DN 50, while model K 330 is used for larger nominal diameters DN 65 up to size DN 100. Should the control medium fail, both guarantee actuation of the control valve to the safety position. The fabric-backed seal diaphragm has certainly proved its worth. A contoured rim on the rubber diaphragm behaves like an O-ring, preventing the control air from being released via the seal surfaces of the actuator diaphragm.

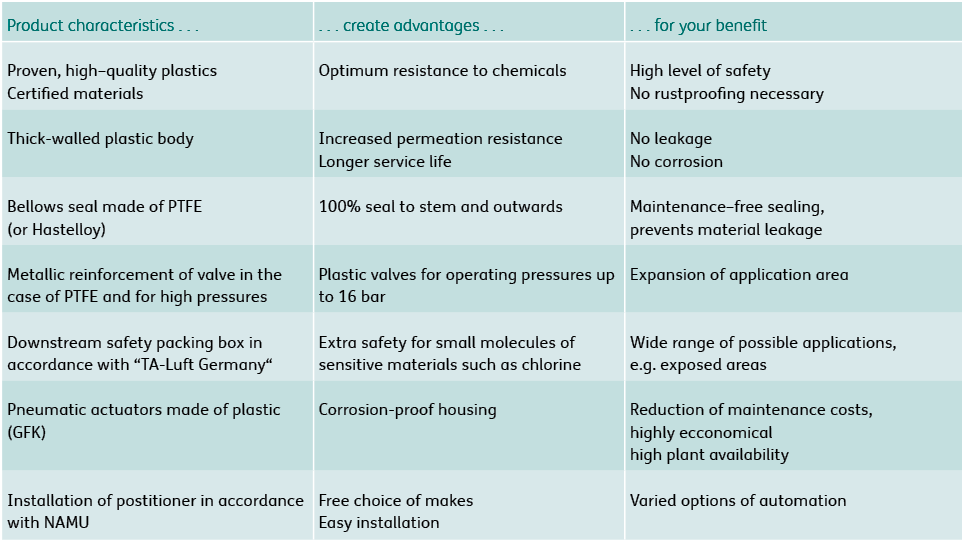

Advantages

The ideal trim set for any application

The control trim set forms the heart of the control valve and consists of the plug head with its characteristic curve and the defined seat. We manufacture this trim set from the same materials as used in the body or from special materials such as Hastelloy C4 or titanium. To seal off components subject to static load O-rings made of EPDM or FPM, or Teflon-coated rings are used. The most important seal to the stem is the maintenance-free bellows made of PTFE.

Materials:

Flow characteristics and cv-values

With the latest software flow gradients can be realistically simulated. EXNER valves provide the possibility to choose different regulating characteristics and selectable Cv – values; this enables selection of an ideal control valve for any application.

The EXNER globe control valves stand for highest quality and are used even under difficult conditions such as for chemical/ chlorine applications or industrial water treatments as well as for chemical- and milk of lime systems. The valves have especially proven their worth for dosing mineral fillers in paper mills: There, milk of lime control valves type 680 are often used.

With ATEX approval

EXNER control valves Type-640Ex and -650Ex with ATEX approval (II 2G IIA) fulfill the technical guideline 94/9/EG. In the nominal diameter range from DN 15 up to DN 100 and pressure range of up to PN 10 they cover most application possibilities in explosion protected areas.

Body material:

Type 610: On-/Off-Valve, DN 15 up to DN 100

Type 620: Pressure relief valve, DN 15 up to DN 100

Type 630: Manual control valve, DN 15 up to DN 100

Type 640: Control valve with electrical or pneumatic actuator, DN 15 up to DN 100

Type 650: Control valve with electrical or pneumatic actuator, DN 15 up to DN 100

Type 680: Milk of lime control valve with electrical or pneumatic actuator, DN 25 up to DN 80